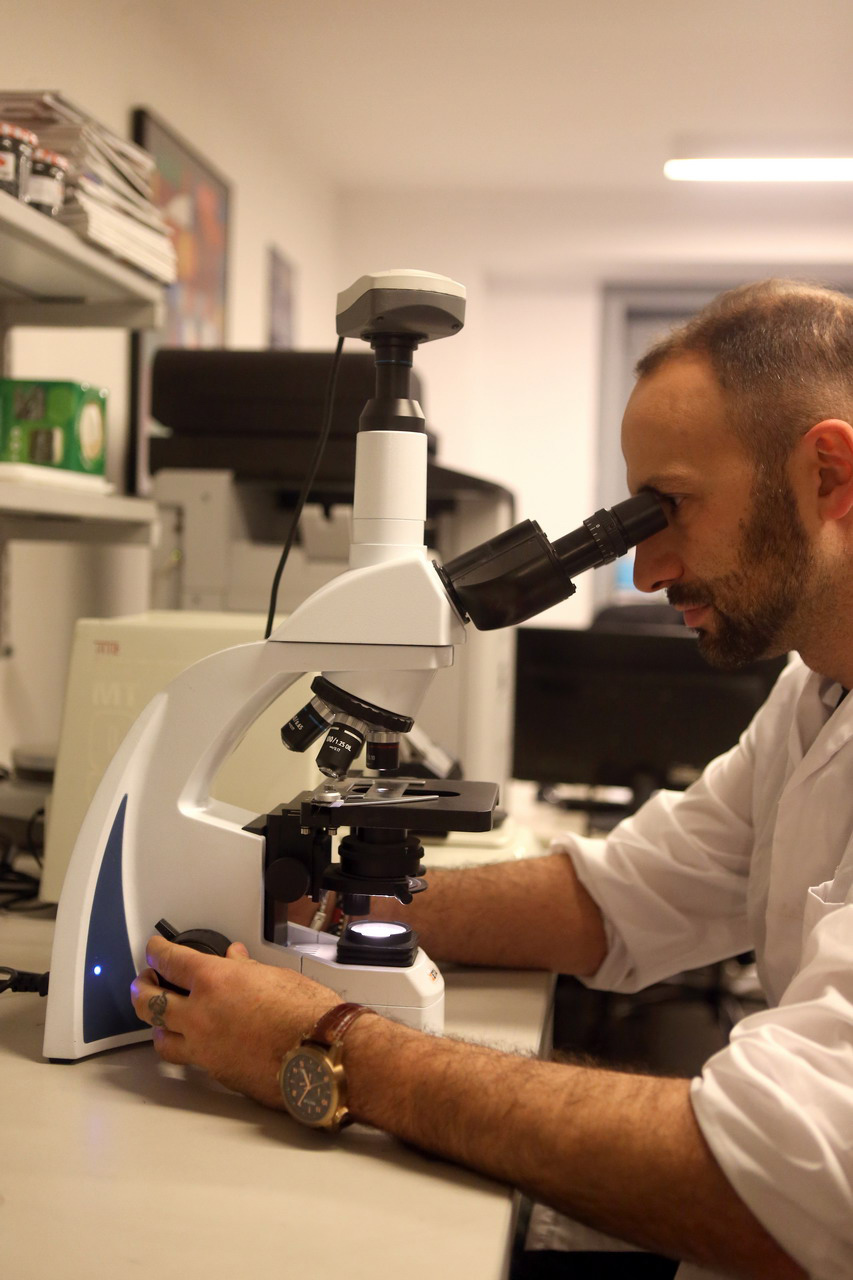

The lab is at the heart of Pebo’s success.

Tests are carried out on various plastic materials using sophisticated and technologically avant-guard equipment used to approve incoming raw material quality and guarantee quality throughout the production chain up to despatch.

A fine selection of raw materials and an accurate blending prior to extrusion are the secret of Pebo quality focused at supplying our customers with high performing compound.

Laboratory Test

| TYPE OF TEST | NEEDS |

|---|---|

| M.F.I (g/10min) | It certifies the fluidity of the material |

| Density(g/cm3) | It certifies the density. The products can then be classified as either high or low density |

| D.S.C. (min) | used to identify any contamination of other materials: for example, if there is any polypropylene component |

| O.I.T. (min) | resistance to oxidation; aging |

| Water content (ppm) | to check for the presence of water. Water is considered a pollutant |

| TGA – Carbon black content (%) Inorganic fillers (%) |

cTo check for the percentage of carbon black content and for the presence of inorganic fillers |

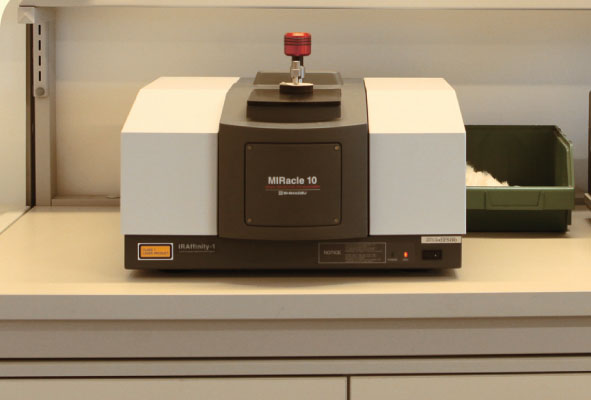

| FITR | To identify the type of plastic present in the compound |

Lab Machinery

FTIR MACHINERY

It is used for raw material identification tests, qualitaty analysis of plastics, analysis of contaminant

DSC Differential Scanning Calorimetry

This equipment determines the transition temperature of materials from a solid state to a liquid one by means of controlled temperature variations. Typicol DSC applications are: determination of the meeting point, phase diagrams, crystallinity of semi-crystalline materials, specific thermal capacity, oxidative stability, decomposition onset and compatibility.

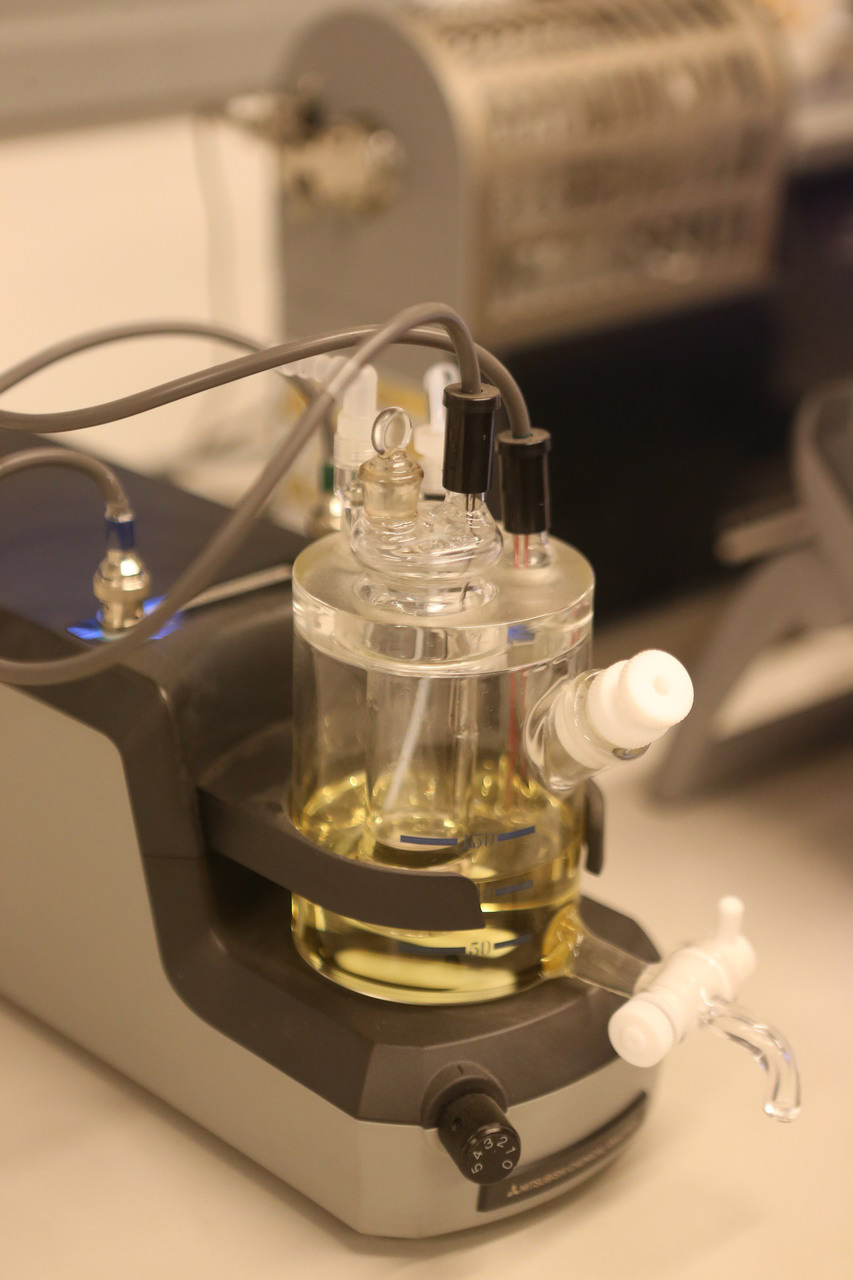

KARL FISCHER COULOMETER

It is suited for water content analysis in raw materials (final products)

MELT FLOW MODULAR LINE

It is used to calculate the Melt flow index of materials both at the start and at the end of the production process. Melt flow index or MFI measures the fluidity of a melted thermoplastic polymer.

The method is described in the similar standards ASTM D1238 and ISO 1133

TGA – THERMOGRAVIMETRIC ANALYSIS

It is a thermal analysis method used to obtain information on material thermal stability and composition. A thermobalance is used to measure the mass variation of a sample versus temperature or time, under a defined and controlled environment with respect to heating rate, gas in the environment, flow rate, crucible type…