Optical sorting is a pivotal innovation in the plastic processing industry, designed to enhance product purity and efficiency. This advanced sorting equipment utilizes a combination of cutting-edge technologies, including high-resolution cameras, sophisticated lighting systems, and machine learning software, to meticulously sort and eliminate product defects and foreign materials based on color, shape, and texture.

The key to this technology lies in its precision. Product tracking software accurately classifies each particle as accepted or rejected, significantly minimizing the recirculation of unclassified granules. This not only reduces energy consumption but also decreases wear on ejectors and downtime associated with clearing product build-up.

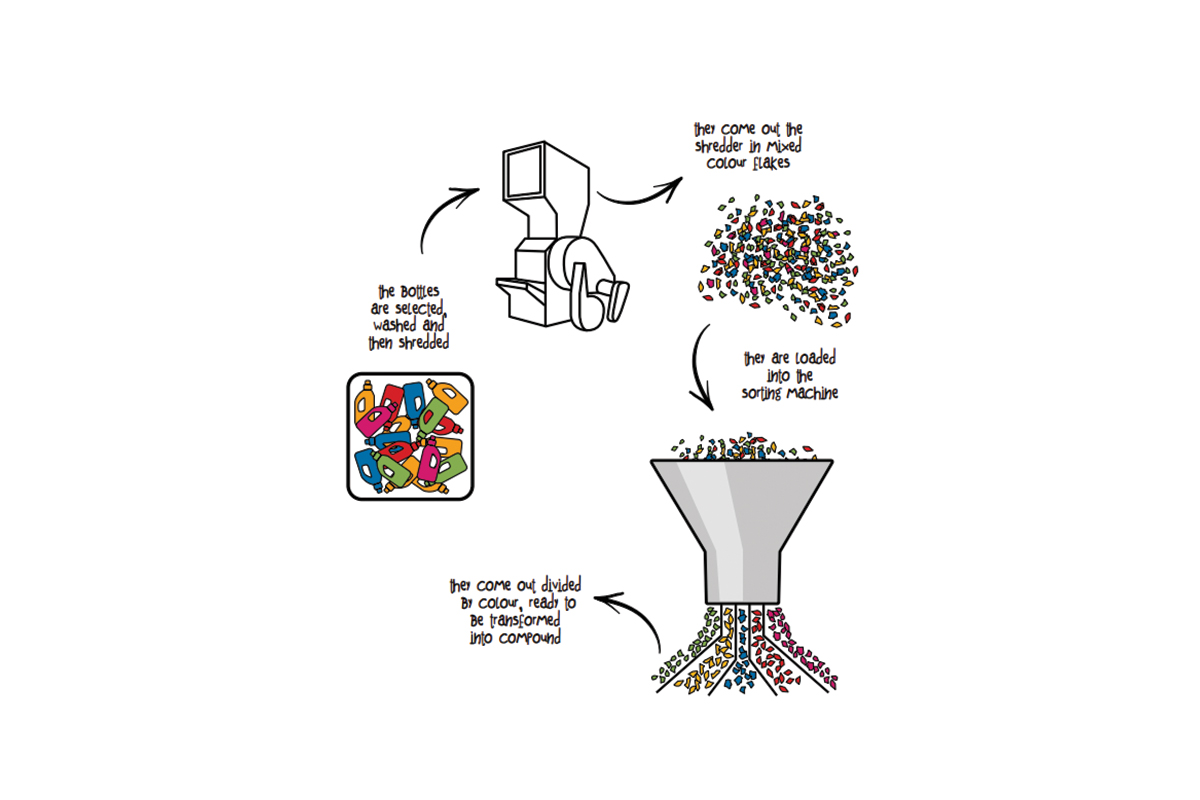

Specifically tailored for processing high-density polyethylene (HDPE) products, such as milk bottles, bottle caps, and shampoo bottles, optical sorters are adept at removing common contaminants like colored polyethylene (PE) and polypropylene (PP), packaging labels, and even non-plastic materials such as aluminium and wood. This capability is crucial for meeting the stringent requirements for obtaining near-pure resin streams.

The benefits of employing optical sorting technology extend beyond the removal of contaminants. It also enables the production of granules with a more homogeneous and consistent color for each batch, significantly enhancing the quality of the final product. This technological advancement represents a significant step towards sustainable and environmentally friendly plastic processing, aiming for a future where quality and sustainability go hand in hand.